The weighing label printing software is mainly used for the quantity conversion with the actual weight of the electronic scale in the process of warehouse receiving, production issuing, outsourcing issuing and product packaging to prevent errors or inspection errors, that is, to prevent the operator from loading more, loading less, loading wrong and faking, to give an alarm for the above situations, to prevent errors in time, to reduce the return and rework of products, and to improve the work Efficiency, avoid customer complaints.

Weighing label printing software system architecture

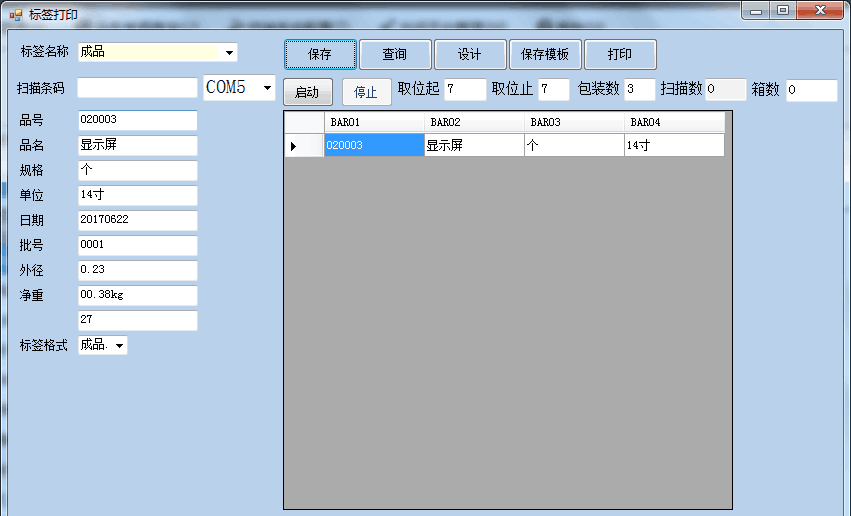

Weighing label printing software printing interface:

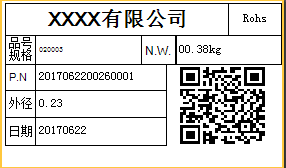

Weighing label printing software label printing example:

Weighing mode of weighing label printing software:

Mode 1: automatic label printing for comparison of weighing number and standard number

A. Enter the basic data of product data, single weight, tare weight and positive and negative tolerance.

B. It can directly read ERP data and directly write back weighing results to ERP system to realize seamless docking.

C. Scan product bar code to automatically bring out the standard weight of the product, realize online comparison of weighing results, and automatically print labels if the results are consistent, otherwise, an error alarm will be given.

D. Support one computer to connect multiple scales.

E. Supporting equipment: scanning gun, electronic scale / weighbridge, printer, audio, alarm.

Mode 2: weighing number and standard single weight calculated product quantity

A. Enter the basic data of product data, single weight and tare weight.

B. It can directly read ERP data and directly write back weighing results to ERP system to realize seamless docking.

C. Scanning product bar code automatically brings out the standard single weight of the product, realizing the calculation of the product quantity based on the weighing result, and automatically printing the label if the result is consistent, otherwise the label will not be printed.

D. Support one computer to connect multiple scales.

E. Supporting equipment: scanning gun, electronic scale / weighbridge, printer.

Mode 3: automatic label printing with actual weighing

A. Enter the basic data of product data, single weight and tare weight.

B. It can directly read ERP data and directly write back weighing results to ERP system to realize seamless docking.

C. The product information will be automatically brought out by scanning the product barcode, and the label will be automatically printed based on the actual weighing results.

D. Support one computer to connect multiple scales.

E. Supporting equipment: scanning gun, electronic scale / weighbridge, printer.

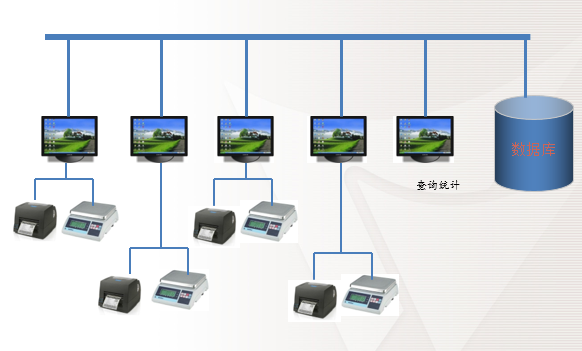

Layout description of weighing label printing software:

1. Each weighing place is equipped with a computer, and the electronic scale and printer are connected to the computer.

2. Each computer forms a local area network through a network cable.

3. Put a better configured computer in the engineering department to serve as a server, and the database is deployed on this computer, so the weighed data are saved on this computer.

4. You can query or count data on any connected computer