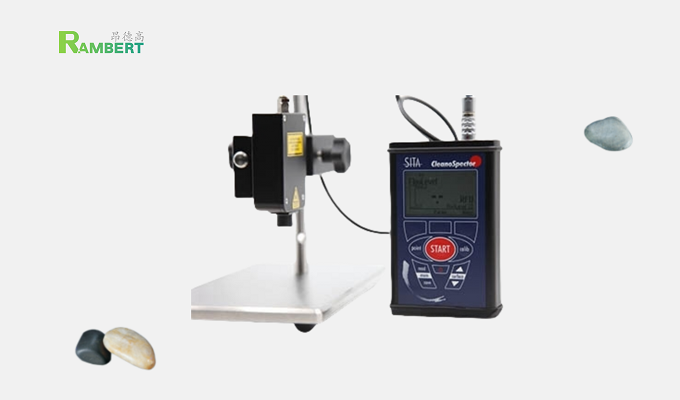

The surface cleanliness tester is used for inspecting the surface cleanliness of metal in industries such as electronics, electrical appliances, automotive vehicles and components, electroplated hardware, military, circuit boards, and batteries before painting and welding. The SITA surface cleanliness measuring instrument adopts fluorescence measurement technology, which is characterized by high sensitivity, rapid testing, and non-contact non-destructive measurement, and has become a leading and recognized non-destructive testing technology for surface cleanliness. In this technology, German SITAMesstechnik GmbH has more than 20 years of rich experience in the research, development, production, and global application of portable equipment and integrated online detection systems for industrial manufacturing.

The SITA CleanoSpector surface cleanliness measuring instrument developed by German SITA can detect even very small amounts of organic pollutants such as grease, lubricating oil, coolant, and wax on the surface of metal (glass, ceramic) through fluorescence measurement technology, ensuring that the cleanliness of metal parts for deep processing such as surface painting and treatment meets the requirements. This prevents the adhesion and firmness of the coating and adhesive bonding layer from being severely reduced due to residual pollutants on the surface during production processes such as painting, bonding, and welding.

Based on the test results, the surface cleanliness measuring instrument can provide reliable data for parameters such as cleaning time, chemical process, and soaking temperature in the entire cleaning process. It ensures that products meet high-quality requirements by monitoring the quality of metal parts. At the same time, staff can review production steps and optimize the cleaning process to improve work efficiency and reduce rework rates, meeting customer quality requirements. It can be seen that the German SITA surface cleanliness measuring instrument assists in stabilizing the cleaning quality during parts processing and achieving quantitative control!

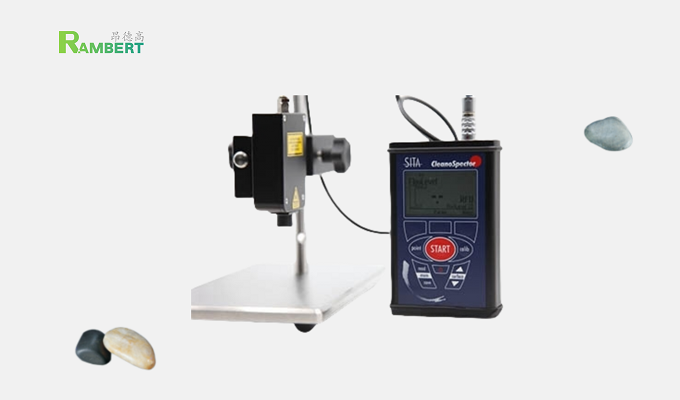

The SITA CleanoSpector surface cleanliness measuring instrument is a portable testing device for part surface cleanliness with simple operation. It provides two ways to display measurement results for users to choose from:

Fluorescence is a form of luminescence that refers to the emission of light after atoms or molecules are excited, known as photoluminescence when photons are emitted. The fluorescence mechanism is shown in Figure 1. To excite fluorescence, an ultraviolet light source is used to irradiate the surface of the test piece. Pollutants on the surface of the test piece absorb high-energy radiation (1). Excited by photons, the electrons of the pollutants reach a higher energy level (2) - the excited state. The excited molecules collide with their environment and release a small part of the absorbed energy (3). The remaining energy is released as emission (4), and the electrons return from the excited state to their original state. The emitted photons have lower energy, thus releasing longer wavelengths (5).

In simple terms, ultraviolet light excites fluorescence. When pollutant electrons absorb photons, their energy increases, causing an electron cloud transition from a low energy level to a high energy level. However, the high-energy state is unstable, so the electrons return to their original energy level and release energy. Since part of the energy is consumed as heat, the emitted photons have lower energy and longer wavelengths.

The test parameters of the SITA surface cleanliness instrument are appropriately designed for common cleaning process pollutants. Because organic matter has a strong autofluorescence characteristic when excited by UV light, the instrument can detect organic pollutants such as grease, residual surfactants, and lubricating oil. It can also monitor the thickness of oil film layers such as preservatives or adhesives.

The above figure shows the fluorescence spectra of cooling lubricating oil and three different oils excited at a wavelength of 365 nm. Since they all have the strongest fluorescence intensity at a wavelength of 460 nm and can be detected for fluorescence values, the SITA surface cleanliness measuring instrument uses this wavelength to detect pollutant content.

The SITA CleanoSpector surface cleanliness instrument uses a confocal method. It emits UV light of the optimal wavelength through a light source to detect pollutants on the metal surface, while a sensor on the other side detects the fluorescence intensity, which depends on the organic residue at the test point. Therefore, the probe can be flexibly positioned, and online measurement is easy to achieve.

With the combined effect of the UV light source and the sensor, the surface cleanliness instrument can quickly quantify test results to directly determine whether the cleanliness of the part surface meets the qualified range. The quantification of surface cleanliness helps stabilize the cleaning quality during parts processing, effectively avoiding phenomena such as reduced adhesion caused by oil stains on the product surface and virtual soldering or desoldering during welding, ensuring that the final product quality meets the requirements.

| Measurement Principle | Confocal method, non-destructive surface cleanliness testing via fluorescence emitted by a UV light source |

|---|---|

| Measurement Units | a. Percentage (%), indicating surface cleanliness; b. RFU value, indicating relative fluorescence intensity |

| Detectable Pollutants | Organic pollutants such as oil stains, grease, cooling lubricants, and wax |

| Calibration | Automatic calibration on a clean metal surface |

| Calibration Parts | Can be calibrated on different surfaces (steel, copper, aluminum, gold, etc.) |

| Number of Measurement Points | Can be personalized according to the tested component |

| Diameter of Measurement Point | 1 mm |

| Optimal Measurement Distance | 4.7 mm |

| Display | LCD with backlight |

| Number of Archived Files | 254 |

| Memory | Each file can store 8,000 measurement values |

| Power Supply | Rechargeable lithium-ion battery/power adapter/USB |

| Weight | 530 g (including sensor and handheld accessories) |