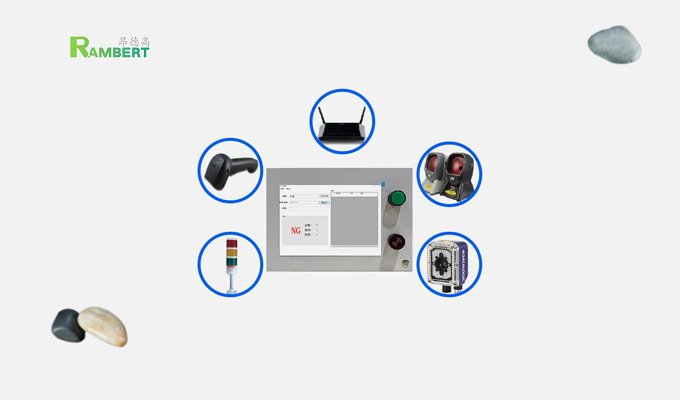

RS1 Production Line Barcode Anti-Duplication, Anti-Error, Anti-Fooling and Anti-Mixing Scanning System

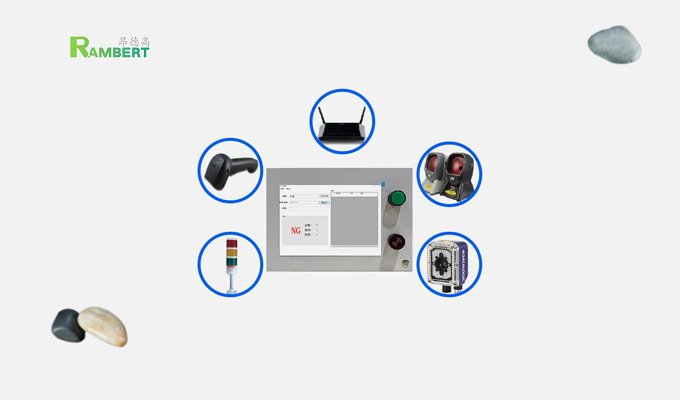

The RS1 production line barcode anti-duplication, anti-error, anti-fooling and anti-mixing Datalogic scanning system is a barcode detection system developed by Shenzhen Ondgo for preventing product mixing, barcode duplication, missing barcodes (or printed barcodes), and missed scans during production lines, packaging lines, and warehouse sorting.

Barcode Error Prevention System: In production lines, packaging lines, and during product warehousing and outbound processes, most factories still rely on manual sorting and packaging due to technical, quality inspection, and product characteristic reasons. Manual operations inevitably lead to omissions, which may cause significant losses to factories. For example, underloading, overloading, and misloading often occur. Once such issues arise, multi-party coordination may be required, increasing labor costs, production costs, etc. Therefore, barcode error prevention systems are indispensable in industries such as production lines and logistics. Combining numerous customer cases, Aushen Barcode has developed a barcode error prevention detection system. The system adopts barcode technology and can effectively carry out label error prevention, packaging error prevention, barcode error prevention, product fool-proofing, etc.

There are two detection methods available for selection:

1. Unique barcode fool-proof system to prevent the mixing of other barcodes;

2. Serial number barcode detection to prevent the mixing of products from other batches and products with duplicate barcodes.

Unique Barcode Detection Preset the detection barcode. Each time a barcode is collected, it will be compared with the preset detection barcode. If they match, "OK" will be displayed and the product quantity will increase by 1. If they do not match, an alarm will be prompted, and the administrator password will pop up. The data is saved in the collection terminal device.

Serial Number Barcode Detection Preset the starting barcode A. The next collected barcode must be A+1. Otherwise, the collector will prompt an alarm, pop up the administrator password, and save the data in the collection terminal device. ### Project Advantages - **Convenient Installation**: Simply install the scanner on the production line for immediate scanning, with a hassle-free installation process. - **Easy Operation**: Features an interface style similar to Wince and Win7 systems, displaying barcode content with "OK" or "NG" status, accompanied by alarm prompts. It also supports functions like production line shutdown and product rejection. - **Plug-and-Play**: Employees can start operating after just a few minutes of simple training. - **Diversified Detection**: Capable of detecting duplicate barcodes, incorrect barcodes, unreadable barcodes, barcodes not in the database, etc., through multiple methods. ### Recommended Collection Methods To improve detection efficiency, we recommend adopting an automated barcode data collection method using a fixed barcode scanner. When the system alarms, the collector can control the production line to stop, reducing manual interference and enhancing work efficiency.