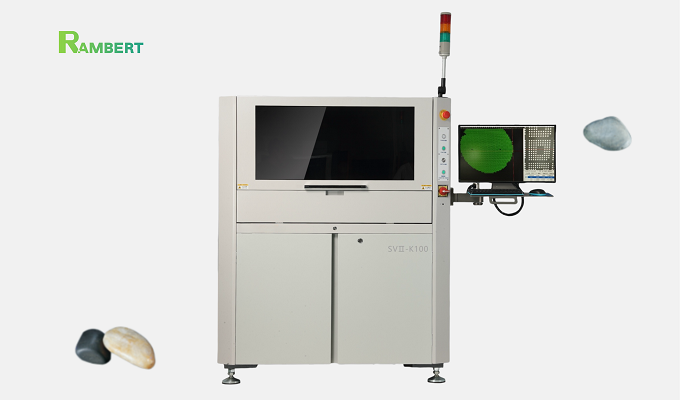

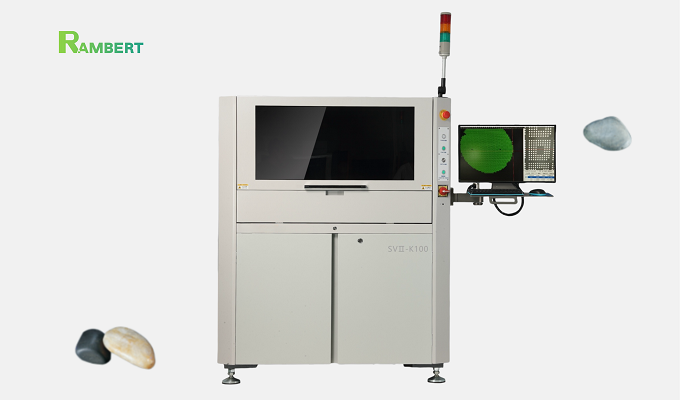

This is the first and leading fully automatic stencil inspection machine in China, which can solve all the problem for making and cleaning the stencil, improve the cleaning process, establish stencil management standard, improve the production management system, automatic inspection instead of manual checking, reduce the labour cost, improve the products quality as well as solve the excess solder, insufficient solder short problem at the very beginning.

Process Improvement

Solve the problem in receiving and cleaning the stencils, improve the cleaning process

Establish stencil management standard, improve production management system

Automatic inspect instead of manual checking, improve products quality

Solve the excess solder, insufficient solder short problem at the very beginning.

The 01005 component or even more smaller component are widely used in the production now, high precision inspect is needed for future development.

Designed for Precision

High-speed Linear Motor (magnetic suspension transmission) movement and control drive device, applied with DKM adjustable liner motor driving module to ensure the high precision of the liner movement, and avoid the low precision issue occurred due to the corrosion after used the traditional lead screw for a long time.

Features:

Input GERBER data and modularizing the data structure. The results can be viewed after immediate measuring within 3 min.

Input CAD file, the inspection data can match with SPI immediately, then can go back to check.

It combines the different SPC analysis automatically, so it resolved and standardized the design of the stencils, and to guide the application for our clients promptly and easily.

Inspect for apertures area, position, offset, size, foreign objects, burr, hole clogging, miss hole, tension and solder paste all printed data etc. of stencil

The open type of communication protocols can communicate with in-line real time system or machine in the market. All stencil ID number, data and status can be checked at any time.

The fastest speed in the world, it only takes 2 min. to inspect a PCB board with 230mm*150mm, including to check the data and SPC analysis.

The world's fastest detection speed, standard PCB 230 * 150 measurement speed of 2 minutes, including view data structure SPC analysis.

Technical Specification

Testing Specification | |

Application | For 1st time inspection or inspection after cleaning |

Inspection items | Area, position, offset, size, foreign objects, burr, hole closing, miss hold |

Inspection times | 2 minutes (230x150mm standard) |

Capabilities | |

Measurement accuracy of Opening area | Gaga R&R <5.0% (the actual measurement is R&R<1~2%) |

Measurement accuracy of opening position | 10µm |

Transmission mechanism | Reparability ±5µm Servo system (Resolution: 0.5µm) |

Optics | |

Camera | 5M or 12 M |

Lens | Dual telecentric |

Illumination | Special white Led light |

Resolution | 8µm, can make according to requirement |

FOV | 20.5mmx15.6mm (optional) |

Stencil | |

Stencil Size | (736x736) mm maximum (300x300)mm minimum |

Programming | |

Gerber file | RS-274X format (Gerber data teaching) |

Software | |

SPC | Histogram, XBar-R Chart,Xbar-S Chart,Cp&Cpk,% Gage Repeatability Data, SPI Daily/Weekly/Monthly Reports |

Remote maintenance | Team1 Viewer software |

Offline Programming | Offline Programming check |

Computer | |

Brand | Industrial personal computer or work station |

System | Windows 7 Professional Edition 64 bit |

Others | |

Power requirement | 220V, 50/60HZ, Power; 2000W |

Equipment Size | (1200x1200x1500) mm (L*W*H) does not contain three-color light |

Air Supply | 0.4Mpa-0.6Mpa |

Equipment Weight | 1000KG |